usp class vi compliant

Certificates of Analysis COAs report the test results for a specific batch of materials. Specialty Silicone Products SSP provides complete certifications to demonstrate the quality of its SSP-2390 Series USP Class VI FDA and RoHS compliant silicones.

Dursan Passes Usp Class Vi Testing Why Is That Important

Some compounders use USP Class VI compliant ingredients but cant ensure the compliance of their end product.

. 27 rows The USP Class VI compounds must be made from ingredients with clear histories of biocompatibility that meet tighter requirements for leachates. Compliance to USP Class VI is often requested by end users. CLASS VI TEST USP Test Article Watershed 11122XC Author Christopher Parker MS.

Otherwise the molder may use materials that haven. SIMONA PP-H USP Class VI sheet is ideal for applications requiring biocompatibility testing standards defined by ISO 109931. All these special grade products have passed this rigorous test.

A plastic resin material that has passed Class VI certification is expected to be more likely to produce favorable biocompatibility results. USP Class VI materials EPDM Silicone Fluorocarbon and Perfluoroelastomer 24 materials which are compliant to FDA 21 CF R1772600. USP Class VI testing is conducted by producing an extract of the product with different extraction fluids such as polyethylene glycol and vegetable oil and injecting it in specimen rabbits and mice in vivo alive to observe the biological response to the extract.

USP Class VI Compliant Materials for Medical and Pharmaceutical Products Meets USP Class VI requirements for use in medical and pharmaceutical applications. Others may change ingredient suppliers between different orders for the same materials. Has a full range of specialty adhesives epoxies primers for polyolefins UV curables and silicones that have been fully tested to meet USP Class VI requirements.

According to USP United States Pharmacopeia there are six plastics classes ranging from I to VI with class VI being the strictest. Tests are based on material extracts that according to the thermal resistance of the materials are made after contacts and at one of the following temperatures 50 C 70 C and 121C 122 F 158. Typical applications for our FDA NSF 51 USDA materials are disposable medical devices surgical instruments and medical fluid dispensing components as well as a wide variety of food and beverage.

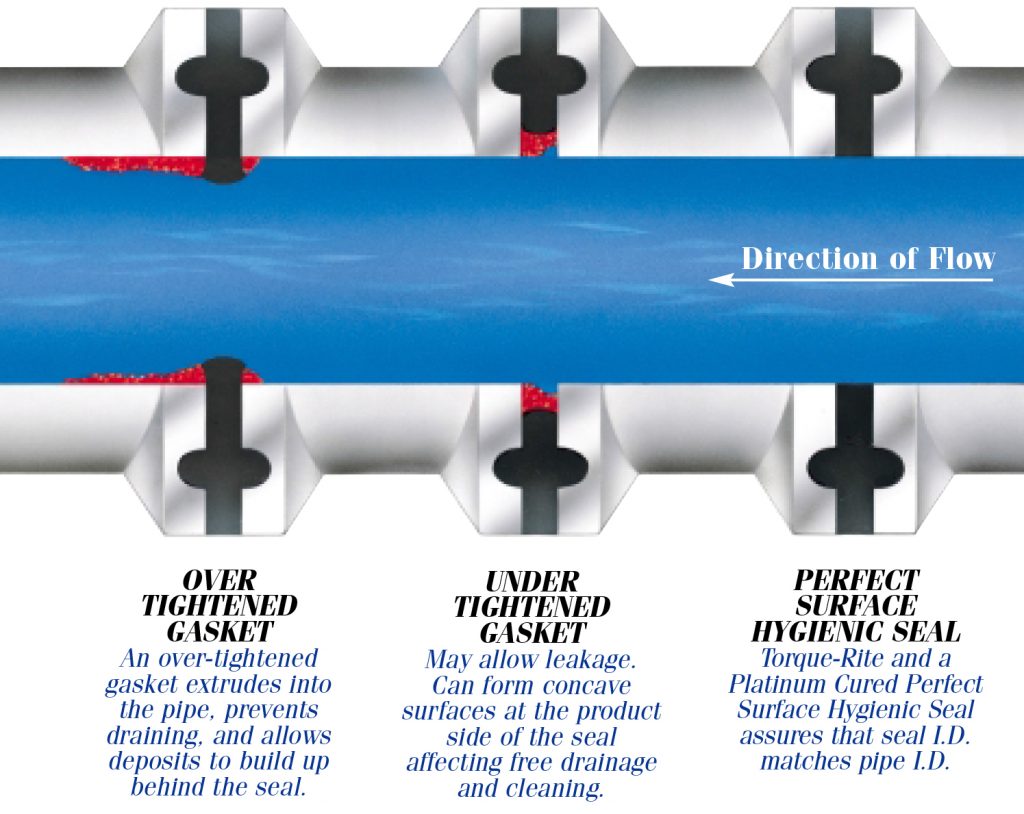

USP Class VI compliant O-Rings N ewmans USP Class VI compliant Platinum Cured Silicone O-Rings are complimented with our Class VI EPDM black or whiteperoxide cured and Viton black or whitebisphenol cured. Class testing is needed when manufacturing drugs to identify its low toxicity compliance while ensuring it meets all biocompatibility standards. While it is possible a USP Class VI material could also be ISO 10993 compliant its not a given and USP Class VI alone is not sufficient for adherence to ISO 10993.

In particular regarding the USP class VI certification process materials have to pass the biological tests ie. Darcoid and Parker offer a wide range of USP Class VI and FDA. An article of commerce that is recognized in the USPNF complies with USPNF standards when it meets all of the requirements stated in the articles monograph applicable General Chapters and the General Notices with monograph requirements superseding those of the General Chapters and General Notices in any cases where requirements differ.

Certificates of Conformance COC attest to a batchs. For plastics they have six different classes based on duration and application. That being said if you cant get an ISO 10993 compliant material often because the material simply hasnt been tested using a USP Class VI material is a less risky option.

USP Class VI testing helps ensure that all materials used in industrial processes are biocompatible with any substances or chemicals they may encounter. Final Report Date June 18 2008 COMPLIANCE 21 CFR Part 58 Good Laboratory Practice for NonClinical Laboratory Studies MANAGEMENT OF THE STUDY Performing Laboratory Toxikon Corporation 15 Wiggins Avenue Bedford MA 01730 Sponsor DSM Somos. The compliance by way of test report from a certified body confirming adherence to these standards is often requested by the companies or projects for which the O-rings are being manufactured.

Pharmacopeia a private non-government organization that promotes the public health by establishing state-of-the-art standards to ensure the quality of medicines and other health care technologies. Many plastics manufacturers find that it is beneficial to be USP Class VI certified especially if the end use. Class VI is the most stringent and requires.

44 0 1909 560 203. Certified USP Class VI Silicones. USP Class VI and FDA White List Silicone and Organic Elastomer Compounds for Healthcare Products.

Testing is commonly done as per USP which requires three types of. Therefore it is. Master Bond systems are very versatile and can be used for both disposable and.

Specially formulated for long term sealing. For a product to pass USP Class VI standards it must exhibit a very low level of toxicity by passing all of the tests requirements. USP stands for US.

One aspect of evaluating whether a device is safe for use is to test the components of the device. The Dursan coating technology improves corrosion resistance by orders of magnitude compared to uncoated stainless steel. Each O-Ring is identified with a batch number and a cure date making them 100 traceable and come packaged in heat-.

Instrument probes tubing fittings filters and regulators exposed to corrosive sampling streams can be made both inert and corrosion resistant by coating the wetted surfaces with Dursan. There are two types of tests used by the USP for class VI O-rings and these apply to all elastomers plastics and polymeric materials. In vivo testing USP.

To mitigate these risks medical manufacturers can ask injection molders about certificates.

Usp Class Vi Foster Corporation

Double Bagged Usp Class Vi Sterile Scoops

Bal Seal Engineering Achieves Usp Class Vi And Iso 10993 5 Compliance For Medical Sealing Polymers Bal Seal Engineering

Usp Class Vi What Is It And How Does It Apply To Elastomers Barnwell

Standard Fda And Usp Class Vi Compliant Materials For All Types Of Hygienic Connections Repassa

Iso 10993 Vs Usp Class Vi Medical Molding And Bicompatible Rubber The Rubber Group

Usp Class Plastics Pacific Biolabs

Standard Fda And Usp Class Vi Compliant Materials For All Types Of Hygienic Connections Repassa

What Is Usp Class Vi Testing Tbl Plastics

Double Bagged Usp Class Vi Liquid Funnels

Why You Need Certified Usp Class Vi Silicones Specialty Silicone Products Inc